Much like a 1990s car tuning expo, the word carbon sparks passion and

fires up conversations! But there’s been a major shift: it’s no longer about

being the one who“puts it everywhere”, but the one who produces the least.

The goal? To fight climate change. Since its inception, Aréa has adopted numerous practices that would today be considered low - impact. Initially designed to optimise our business model in a prudent, reasonable person approach, this mindset now contributes to a relatively limited environmental impact. Still, that’s not enough to avoid taking the issue further. Founded in 1987, Aréa witnessed the transition to the Euro. Another shift is now underway, as we also measure things in tonnes of CO₂. What could have added complexity to our business equation has actually become a fascinating way to question ourselves. And to reinvent ourselves collectively - taking even greater pride in our work and in our street furniture.

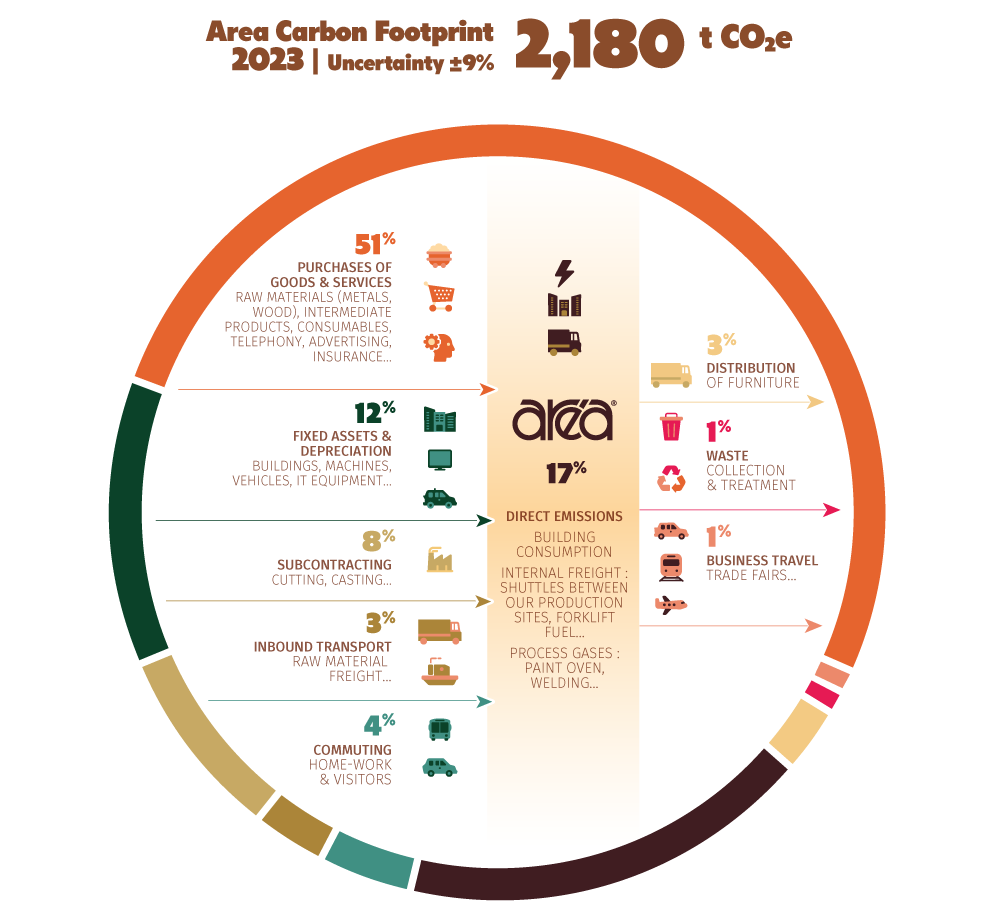

So, we decided to face the figures and carry out a carbon audit, fully aware that - even though our carbon footprint is likely limited thanks to our culture of moderation - there is still room for improvement. One year of commitment later, the result is in: a single figure that sums everything up. Sums it up - but says very little... Desperately searching for some kind of benchmark in this motley inventory, we even found ourselves invoking the memory of Maïté and Micheline (famous french chefs) when faced with the invention of the “duck breast equivalent”! More seriously, this figure is equivalent to the annual emissions of 219 people living in France. Not bad, considering we are 140 people and produced 44,500 products in the year of this first audit!

This brings us to the first key takeaway from the carbon audit: there are only equivalents - no direct comparisons with competitors; no standard benchmarks for a similar activity; not even a ballpark figure for a comparable company. Let’s not pretend: it’s a little disorienting and somewhat frustrating. “Comparison is the thief of joy,” say those whose proverbs could practically be carbon dated (there’s that carbon again!). In our slight frustration, we realised - perhaps unconsciously - that the idea of comparison had been present all along.

But we’ve since come to understand that the only meaningful comparison is with ourselves. Because the point isn’t to be “better than”, or “worse than”, or “even worse than”… but for everyone to be better than they are today. Only then - and then only - can we hope to stay on a climate trajectory that is within our control. So the first benefit of our carbon audit isn’t environmental, but behavioural. It lies in a deep understanding that the challenge ahead is the toughest of all: racing against ourselves.

But let’s return to this desire to explore the environmental impact of our business by undertaking a carbon audit - despite the fact that, given the size of our company, we aren’t legally required to do so. We were confident. We thought we were “doing well”. And while we’re certainly not doing badly, we discovered plenty of room for improvement…

This approach opened the door to a fascinating topic - one that has cast a new light on our work, our production, our organisation… To the point that it has quite literally taken every Aréa employee along on this journey - an open - ended path towards greater eco - responsibility. Because there is almost always a way to do better - meaning, to do with less. Culturally attached to the idea of “Less is more” when it comes to the design of our street furniture, we’ve discovered a new passion for applying this principle to everything that follows the design phase: production, logistics, distribution...

It’s often said that the cleanest energy is the energy you don’t use. What’s true for energy is, of course, also true for materials - steel, wood, and so on - as well as for transport. This principle of good old common sense is deeply embedded in our company’s DNA. And we are grateful, every day, for the foresight of Aréa’s founder in this regard, too. But we now see this culture - which wasn’t yet called eco - design back then - as a starting point, not a destination. A foundation from which to go even further.

Public space planning goes hand in hand with public procurement. In other words: public money. As our street furniture is funded by citizens, it cannot fall short of being exemplary. To understand how we came to embrace this perhaps slightly austere notion of exemplarity, we need to take a step back - and recognise that it all began with passion.

Aréa was founded on our deep passion for public space, and our desire to enhance its comfort, calm, cleanliness and safety - through furniture. For such furniture to be widely installed, it must also be as cost - efficient as possible. This is what led us to eliminate the superfluous at every level. Without realising it, we have practised “design to cost” since the very beginning - known more formally as target costing: a method that integrates cost optimisation right from the design stage. So when our sales team says: “We need a 160cm bench with locally sourced wooden slats and a galvanised steel frame for under €700,” - and when 100% of our products are manufactured within 100km of our Toulouse headquarters - every detail matters. By being mindful of cost, we were - in fact - mindful of materials, energy, logistics, and transport. This constant drive for efficiency has, in turn, made us environmentally responsible. To sum up: We arrived at eco - design through cost - conscious design.

At Aréa, this drive for efficiency doesn’t stop at product design and manufacturing. We aim to eliminate all intermediary costs that don’t create real value for the customer or the end user. Sounds like common sense? We like to think we go a step further - let’s call it “solid common sense”.

It’s thanks to that mindset that we’ve always heated our buildings using offcuts and sawdust from our joinery workshop - rather than paying to have them removed. That we donate larger wood offcuts to the Toulouse School of Fine Arts, where students use them for their projects. That our furniture dimensions are carefully calculated to minimise material waste (and that all steel offcuts are locally re - melted). That we’ve never had a fleet of travelling salespeople - because we’ve worked through direct and remote marketing since day one. That we optimise pallet packing to reduce volume and maximise truck loading, so we can minimise the number of trips.

You might say, “That’s a lot of constraints, isn’t it?” We’d reply: constraints don’t stifle creativity - they fuel it. And we fully accept that we sometimes make life a bit more complicated for ourselves in order to meet the standards we believe in. After all, could we really feel comfortable sitting on a wobbly chair from an ethical point of view? Could we truly believe that aa non - CSR - compliant litter bin serves cleanliness?

It’s fair to say that the most durable products are those that last the longest. In this respect, our sector actually gives us a bit of a head start. Working in an environment - the public space - where extreme sturdiness is a must is a real advantage. Why?

Because when something is sturdy, it lasts. And when it lasts, it’s… durable. Bingo! Designing and manufacturing products that withstand the test of time is the simplest way to consume less. One particularly sneaky form of wear and tear is “going out of fashion” - which leads to discarding perfectly functional items in order to buy new ones that are trendy today but destined to be outdated tomorrow. Keeping a healthy distance from fleeting trends is already a first step on the path to sustainability. That’s exactly what we do. Among our most popular products are a bench designed in 1988 and a litter bin designed in 1992.

To the robustness of the construction and the timelessness of the design, we add two key Aréa principles. First, the absence of any technological elements (solar sensors, USB ports, etc.) that have a shorter lifespan than the furniture itself and would cause premature obsolescence. Second, repairability - ensured by the long - term availability of all spare parts. As a result, our street furniture is genuinely sustainable and can be used for several decades. When they reach the end of their life and are mainly made of infinitely recyclable metals (steel and aluminium), they will be dismantled, melted down, and reborn as radiators, grills, washing machines, beams… or as urban furniture elements - if they have good karma.

The carbon footprint assessment is not a finish line, but a starting point. It is an ongoing challenge, as the potential areas for improvement are virtually limitless. So much so that, in the long run, progress may become infinitesimal. We are not there yet — there are still many aspects to improve, rethink, and invent.

As a major component of our furniture, steel accounts for 50% of Aréa’s carbon impact. More than 90% of the steel we use already comes from recycling. In 2023, this avoided the emission of 598 tonnes of CO₂ — the equivalent of nearly 300 Paris–New York flights. We will therefore need to do better, even though we can only act directly on half of our emissions. What could have slightly discouraged us has, on the contrary, strengthened our motivation. The finalisation of our decarbonisation plan is underway and will constitute the second stage of our approach, following the completion of the carbon footprint assessment. Our next review will take place in 2027. Unless the evaluation methods change, we know we will perform better, with a lower footprint.

Why? Because the topic engages all of us. Take, for example, our well-known 9% Uncertainty Rate — which, we’re told, is quite good. This figure reflects the margin of error linked to approximate data and a calculation method that can still be improved. While we leave it to experts to refine these methods, it is up to us to work with our suppliers to clarify their own CO₂ emission levels. In other words, to encourage them to integrate sustainability issues into their activities — and, where applicable, to carry out their own carbon assessments. This is how the virtuous circle continues: by bringing along those who have not yet embarked on this journey, we are building a network of companies united by the shared goal of reducing the carbon footprint of human activity. This collective awareness is the true purpose behind our work on the uncertainty rate.

A wave of enthusiasm has swept through every part of our organisation. One of the first teams to take up the challenge was Purchasing, which set itself a clear objective: to refine the accuracy of information from our suppliers, ensuring that our figures are neither under- nor overestimated.

Meanwhile, one floor up, a decision was made to install 2,300 m² of photovoltaic panels on the roof of our Flourens factory — a €750,000 investment that now generates half of the site’s annual energy consumption. To improve that figure further, we’d have to adapt our working hours to the seasons: 10-hour days in summer and 5-hour days in winter. Not sure that option would get much support… Within our continuous improvement group, ideas are flying after the complete replacement of all air-conditioning units with programmable models. No more energy wasted at night or on weekends — that’s good, but how can we go even further?

At our manufacturing workshop in Noé, the diesel forklift has been swapped for an electric one. In the offices, everyone has become a human timer, regularly getting up to switch off the lights. The awareness campaign carried out during the full relamping to 100% LED has clearly paid off! And since we’re on the subject of fruit… more ideas are taking root. Our vegetable garden project is nearing completion, and soon we’ll be able to say: “There’s nothing like office-grown organic tomatoes!”